Manufacturing Facilities

Swan Turbines operates cutting-edge manufacturing facilities specializing in the production of a wide array of precision components. Our expertise extends to the manufacturing of Steam Turbine components, including Rotors, Diaphragms, Casings, Blades, Carriers, Bearing Housings, Casings, Bearings, Labyrinth Seals, Oil Seals, and much more. In addition to Steam Turbine parts, we also excel in the production of Compressor Spares, Booster Spares, and Pump Spares, encompassing Rotors, Casings, Impellers, Seals, Bearings, Oil Seals, and various other critical components. Our commitment to excellence in manufacturing ensures that each component meets the highest standards of quality, precision, and durability, contributing to the seamless and efficient operation of diverse industrial systems.

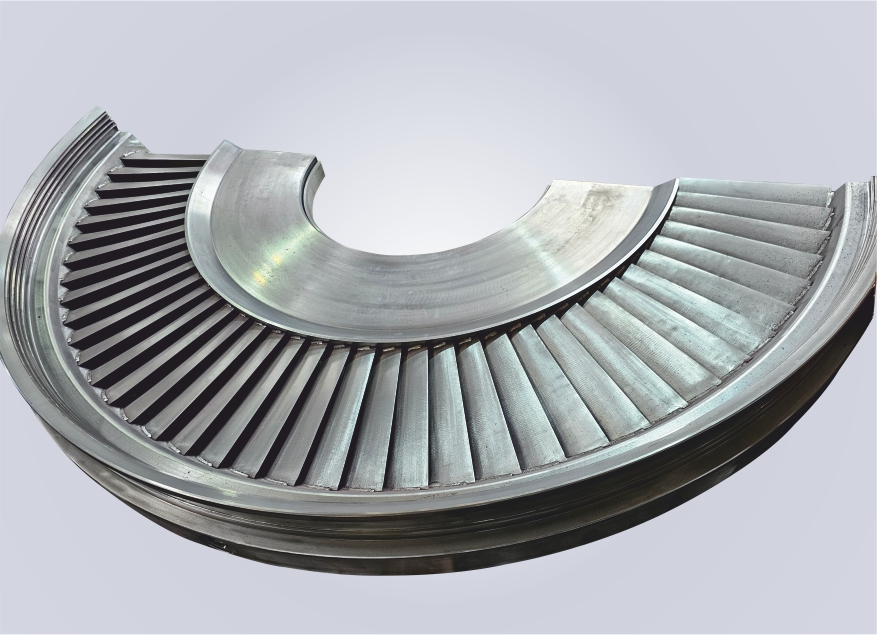

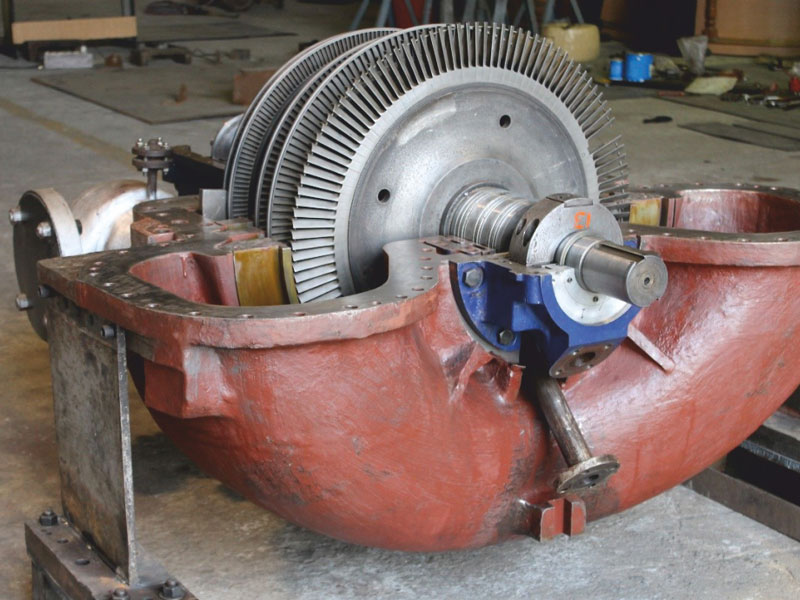

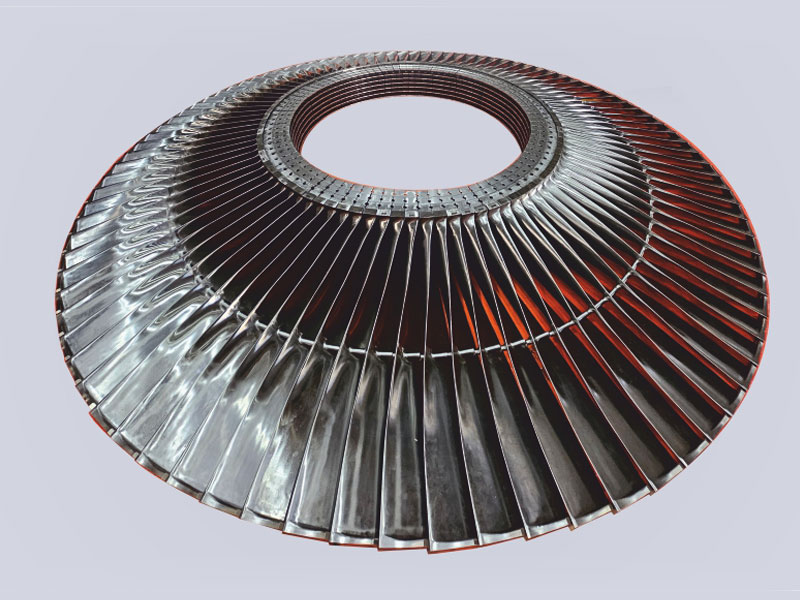

Manufacturing of Guide Blade Carriers and Diaphragms

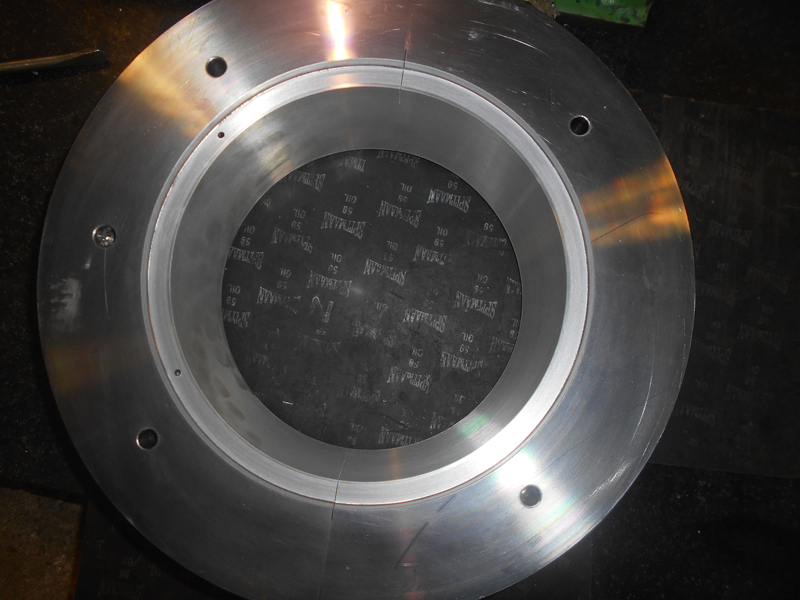

Manufacturing Generator, Turbine & Gear Box Bearings

Generator Bearings

Turbine Bearings

BFP Motor Bearings

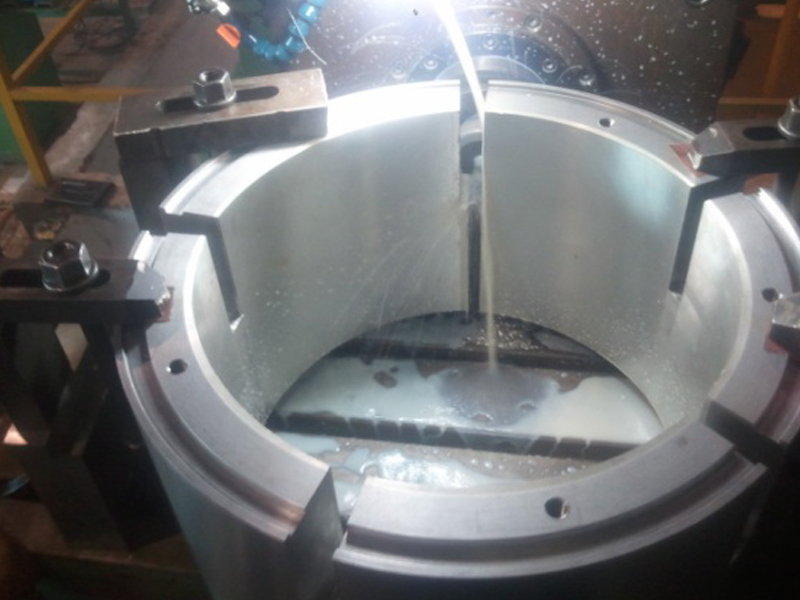

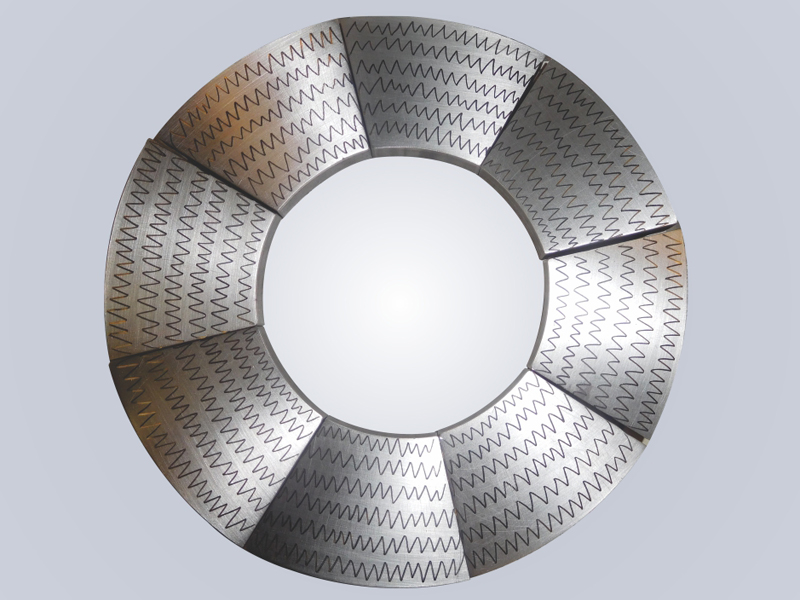

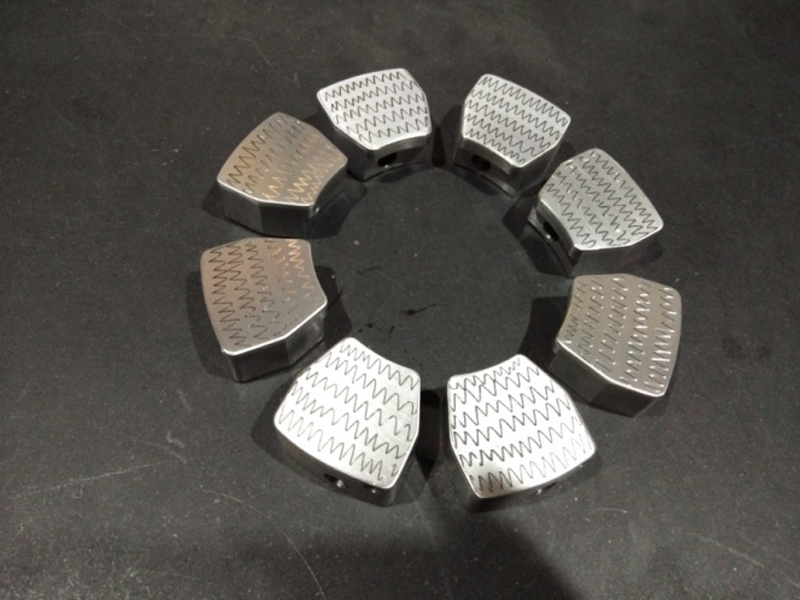

Manufacturing Tilting Pads & Thrust Pads

600MW Tilting Pads

80 MW Thrust Pads

Thrust Pads

New Impeller & Geared Shaft

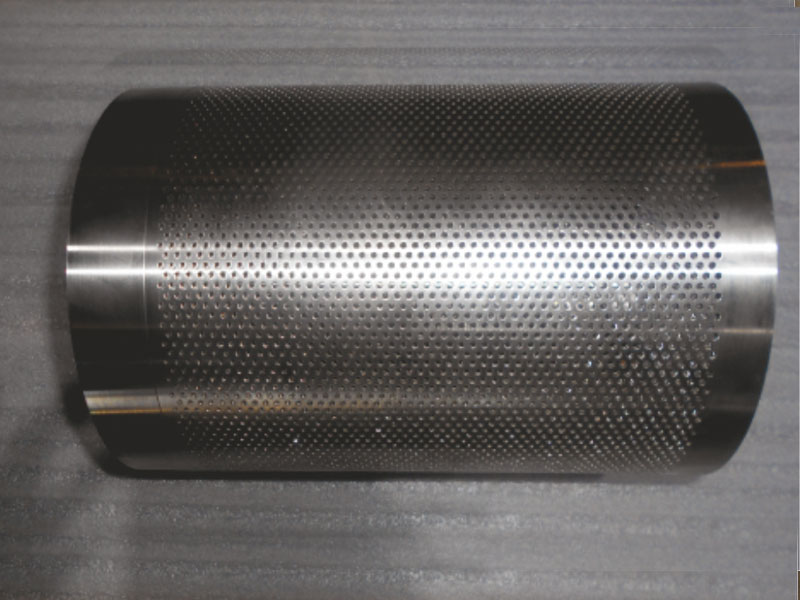

Inter Stage Seals

New Nozzle Segment

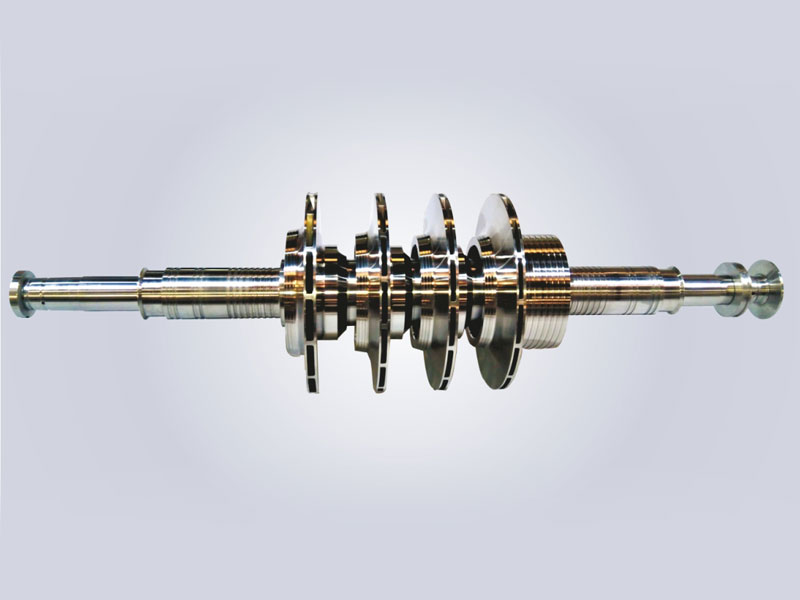

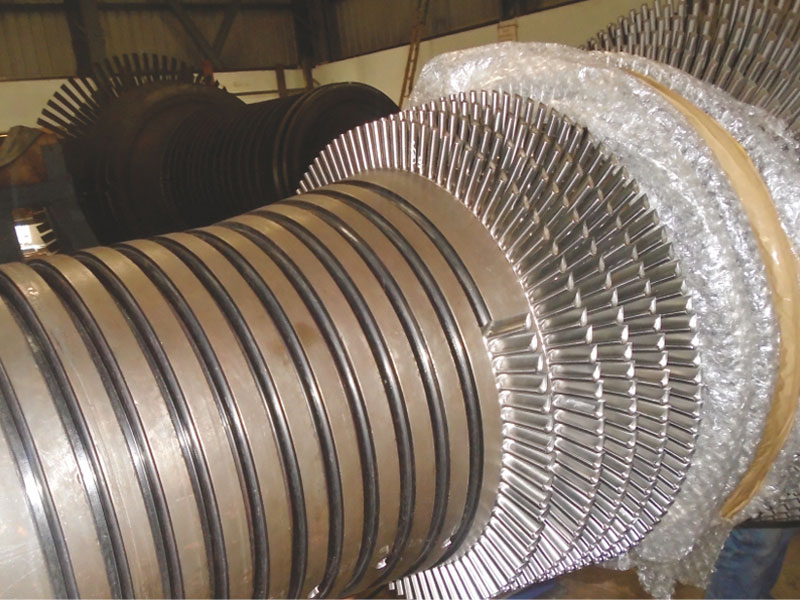

Manufacturing of Turbine rotor

Manufacturing of Compressor rotor

Manufacturing of Turbine Casing

TRT Inlet Guide Vanes

Manufacturing of Governing Valves

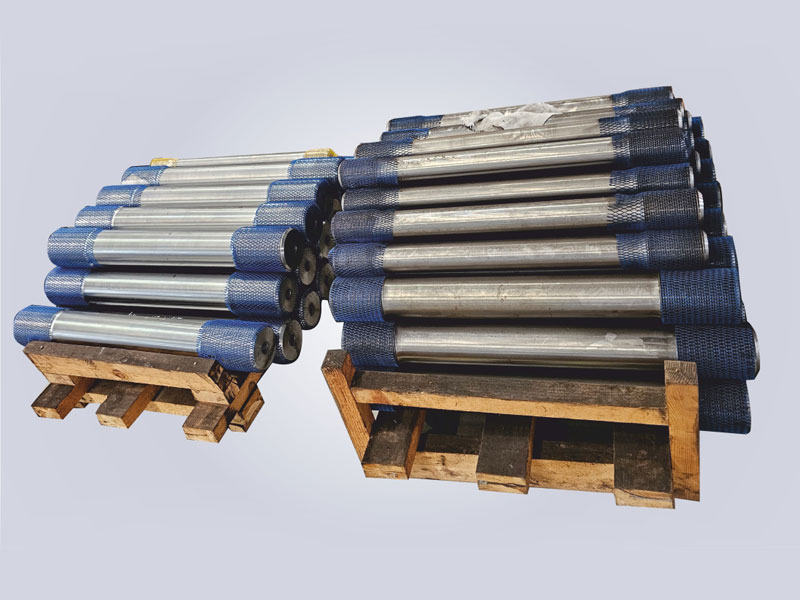

Manufacturing of Studs

300 MW LP last stage blades

210 MW Blades

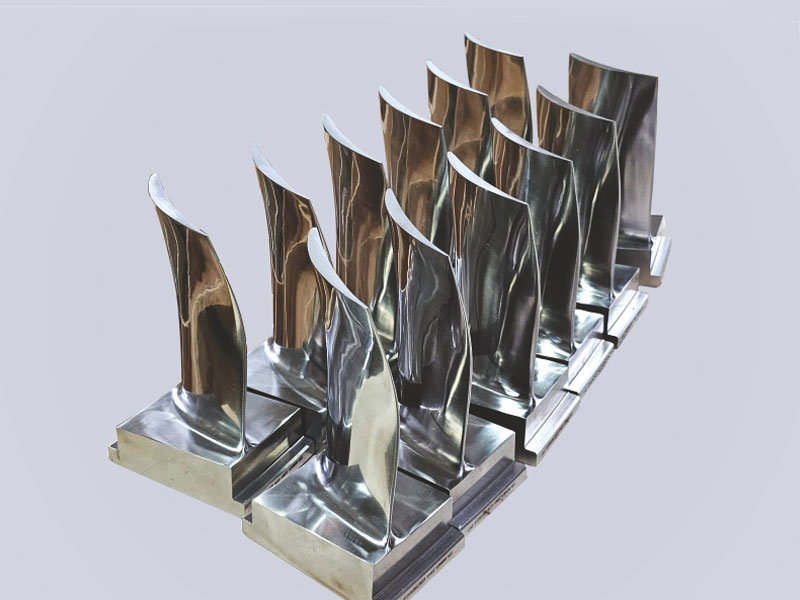

Compressor Blades

300 MW Blades

25 MW Blades Assembly

40 MW SST 300

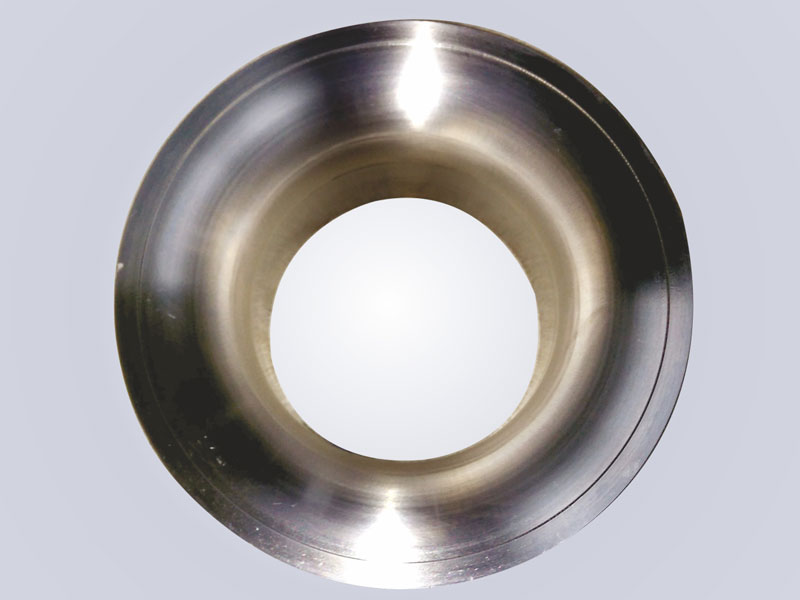

Oil Seal

Steam Strainer

Assembly of Nozzles & L Rings

Diffuser

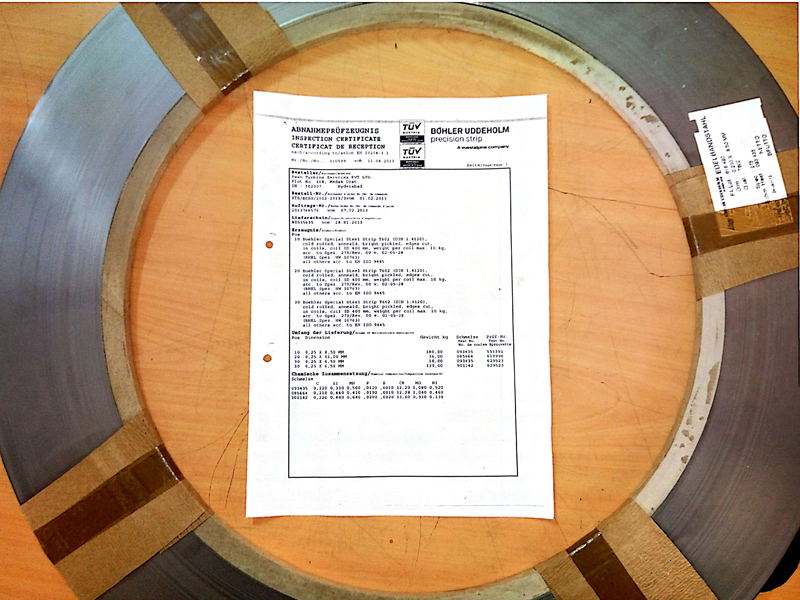

Imported Special Sealing Fin strips (Bohler)

Fin Rolling Equipment

Oil Seal Fins

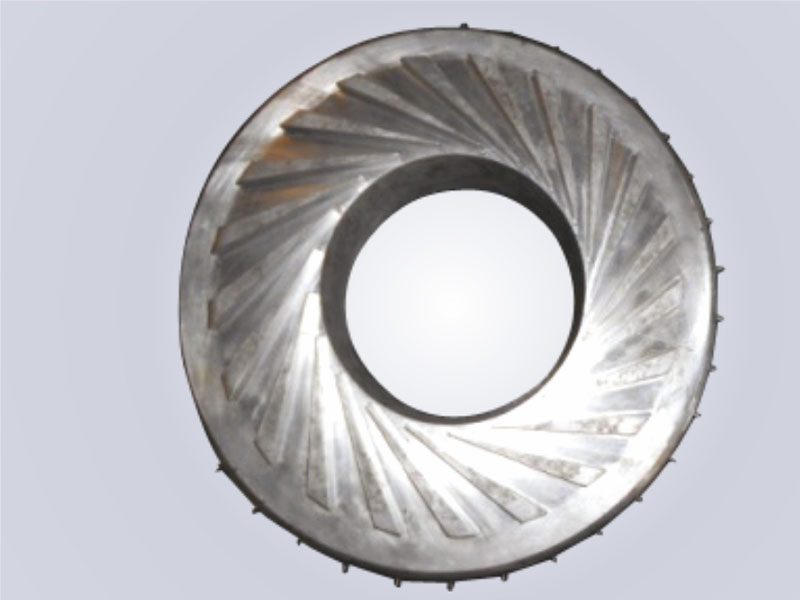

Manufacturing of FD Fan

Manufacturing of ID Fan

600 MW GV Valve Seat

600 MW GV Coupling

600 MW GV Connector

600 MW GV Bonnet inner end Bush

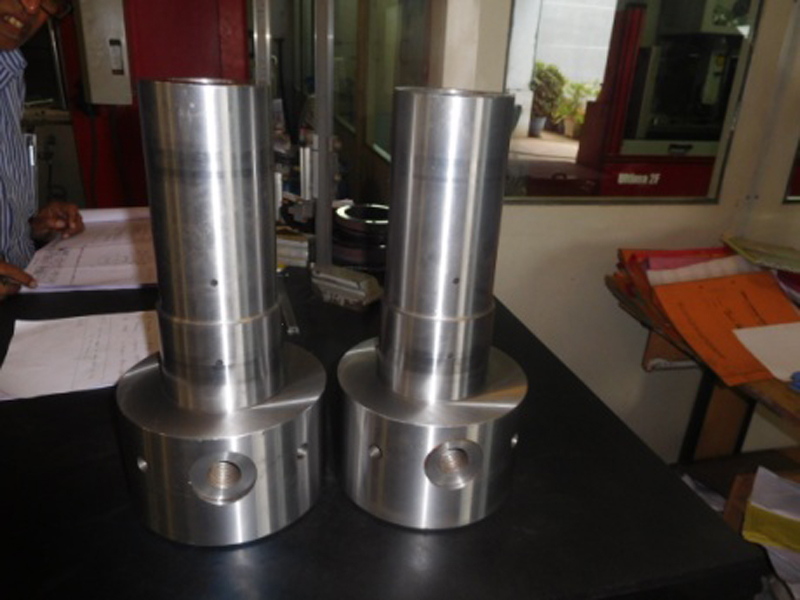

600 MW GV Valve stem

600 MW GV Valve Stem Bushing

600 MW GV Valve Stem Bush

Refining of Rotor

Manufacturing of Allen Bolts

Manufacturing of Taper Pins

Manufacturing of Washers

Reblading of 660 MW HP rotor