In-Situ Machining of Rotors

Our expertise extends to in-situ machining of rotors, journals, shrouds, and slip rings, offering precision refinements for turbine and generator rotors. Dynamic balancing of turbine rotors and on-site field balancing services are tailored to your specific needs. Additionally, our services cover in-situ refining of turbine carriers, governing valve seat replacement, and ESV/MSV valve seat replacement, all conducted on-site for maximum convenience and efficiency.

In-situ Journal machining of 600 MW LP Rotor

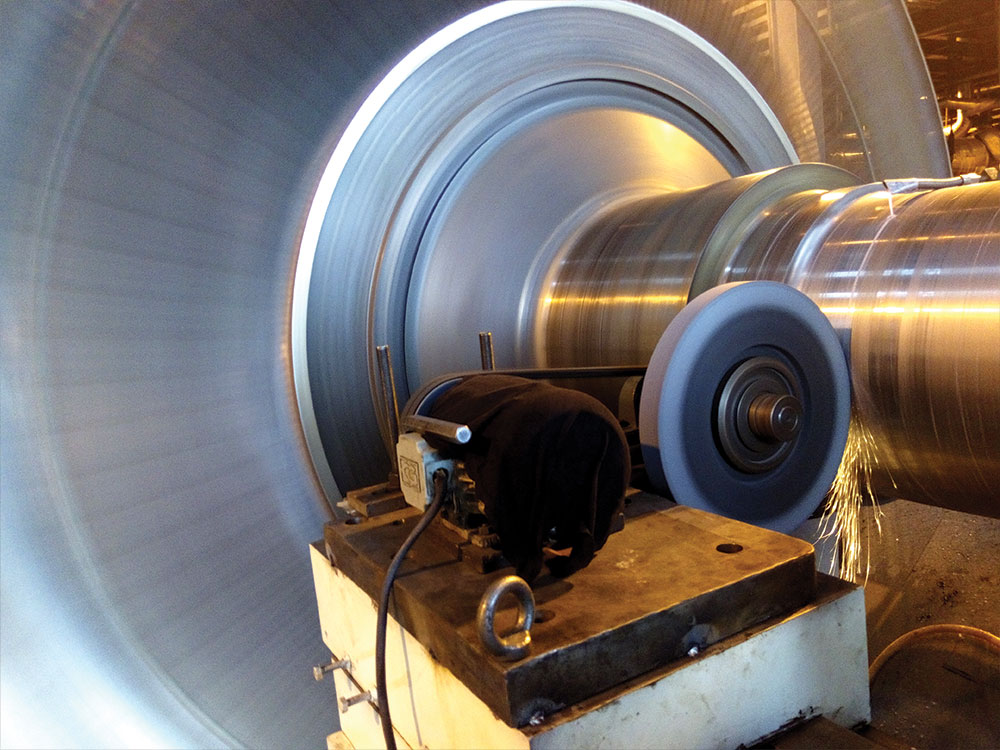

In-situ Journal grinding of 600 MW LP Rotor

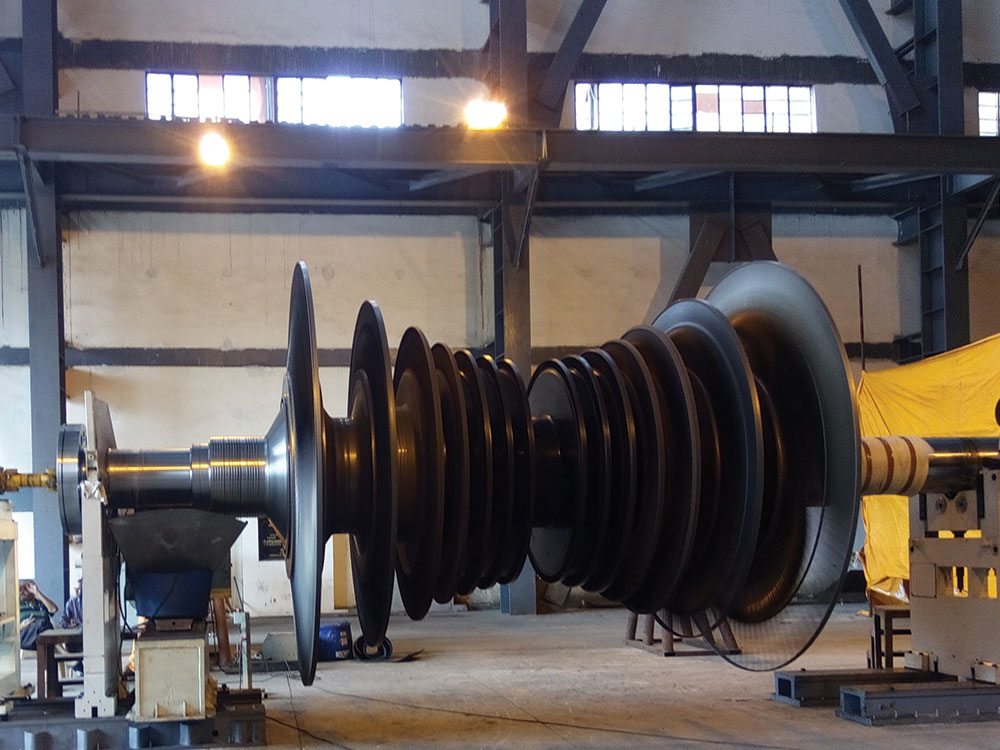

On Site field Balancing of 600 MW LP Rotor

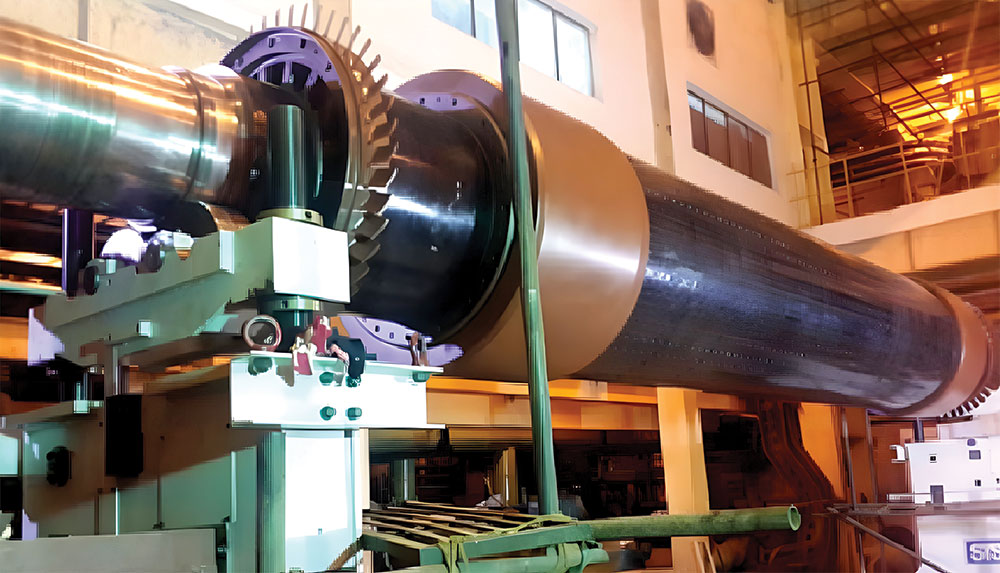

On site field Machining1060 MW Generator rotor

In-situ machining of sealing fins on inner casing and on HP rotor of 200 MW